Dialing in the right Flux Core MIG welding settings can be one of the biggest challenges in the shop. You tweak the wire feed speed, adjust the voltage, and still end up with too much spatter, weak penetration, or even burn-through. Sound familiar? Whether you’re welding mild steel, stainless, or working on different metal thicknesses, it all comes down to balance — and that’s where a good Flux Core MIG Welding Settings Chart makes all the difference.

It helps you match your amperage, wire size, and joint prep to the job, saving time and frustration. Understanding these settings isn’t just about convenience; it’s key to getting cleaner beads, stronger welds, and better control of your arc. In this guide, I’ll break down how to use and fine-tune your flux core settings chart so you can dial in your machine with confidence and get pro-level results every time.

What Is Flux Core MIG Welding and Why Should You Care?

It’s a blustery afternoon on a job site, wind whipping through like it owns the place, and you’re trying to tie two pieces of I-beam together. Gas MIG? Forget it—the shielding gas blows away, leaving you with porous junk. Enter flux core MIG welding, my go-to for when the elements don’t play nice.

It’s like your standard MIG welder got ruggedized: same wire-feed action, but the wire’s tubular, packed with flux that melts to create its own gas shield and slag cover. No external gas needed for self-shielded versions, which makes it portable as hell.

Why care? For DIYers fixing trailers or hobbyists building custom frames, it’s forgiving on rusty or dirty metal—I’ve welded over mill scale that would’ve choked a TIG setup. Pros love it for heavy fab like structural steel or equipment repair because it punches deep into thick plates without preheat drama.

Students, this is your starter process: easier arc starts than stick, less cleanup than oxy-fuel. And for industry folks chasing efficiency, it dumps metal fast—up to twice the deposition rate of solid wire MIG. Bottom line: It’s versatile, tough, and gets you back to beer o’clock quicker.

But here’s the rub—flux core’s got personality. That flux means more spatter and smoke, so ventilation’s non-negotiable. I’ve learned the hard way: Skip it, and you’re hacking up slag for days. When to use it? Outdoors, on thicker mild steel (1/8-inch and up), or anywhere wind’s a factor.

Why? The self-shielding flux laughs at drafts, keeping your arc stable and your weld sound. Pro tip from my shop days: Always drag the gun like you’re stick welding—pushing invites undercut. It’s not fancy, but it works.

Flux Core MIG Welding Settings Chart: Breaking It Down for Real Jobs

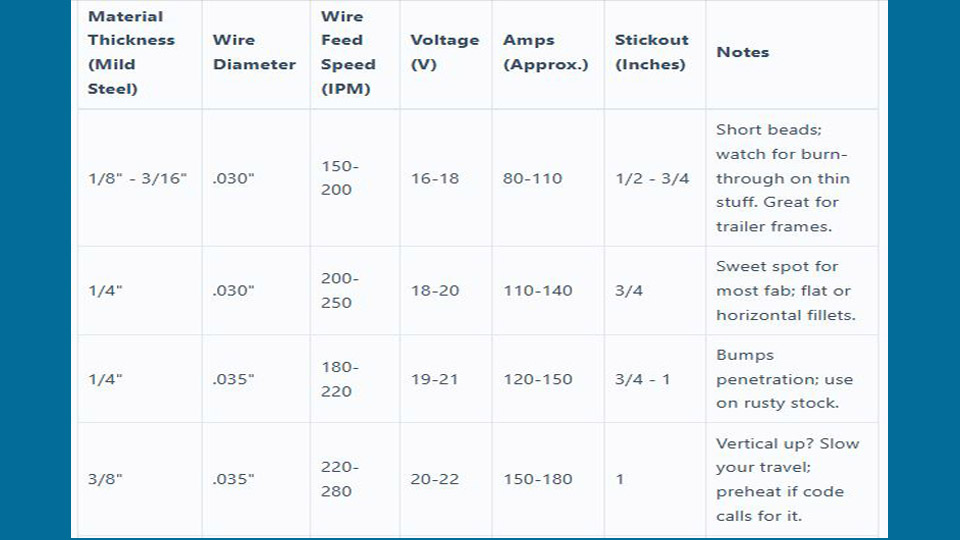

The flux core MIG welding settings chart. I’ve sketched this from years of dialing in machines like my old Miller 211MP and Lincoln Power MIG 210, testing on everything from 1/4-inch angle iron to beefy 3/8-inch plate. This isn’t gospel; it’s a starting point.

Grab scrap, weld a bead, and tweak—your machine, wire brand, and joint setup will nudge it. Focus on wire feed speed (WFS, in inches per minute) for amperage control, voltage for arc length, and stickout (that exposed wire length) for stability.

For self-shielded E71T-GS flux core wire (the workhorse for mild steel), here’s a practical chart. Polarity? DCEN—electrode negative—flip those leads inside your welder if it’s set for gas MIG. Technique: Drag at 15-20 degrees back, 3/4-inch stickout, steady travel speed like you’re pouring coffee without spilling.

| Material Thickness (Mild Steel) | Wire Diameter | Wire Feed Speed (IPM) | Voltage (V) | Amps (Approx.) | Stickout (Inches) | Notes |

|---|---|---|---|---|---|---|

| 1/8″ – 3/16″ | .030″ | 150-200 | 16-18 | 80-110 | 1/2 – 3/4 | Short beads; watch for burn-through on thin stuff. Great for trailer frames. |

| 1/4″ | .030″ | 200-250 | 18-20 | 110-140 | 3/4 | Sweet spot for most fab; flat or horizontal fillets. |

| 1/4″ | .035″ | 180-220 | 19-21 | 120-150 | 3/4 – 1 | Bumps penetration; use on rusty stock. |

| 3/8″ | .035″ | 220-280 | 20-22 | 150-180 | 1 | Vertical up? Slow your travel; preheat if code calls for it. |

| 1/2″ + | .045″ | 250-350 | 22-25 | 180-250 | 1 – 1 1/4 | Heavy structural; multi-pass on thick joints. Check AWS D1.1 for compliance. |

See that? For a 1/4-inch butt joint on A36 mild steel, crank WFS to 225 IPM at 19V—that’s about 130 amps, giving you a ropey bead with good tie-in. I remember fabbing a gate once: Started too hot at 22V, got worm tracks like bad tattoos. Dropped to 19V, and it smoothed out.

Common fix? If the arc stutters, up the WFS a hair; if it’s splashy, trim voltage. Always match wire to base metal—E71T-GS for 70ksi tensile strength mild steel. And prep? Grind to bright metal; flux core forgives dirt, but not paint globs.

This chart aligns with US shop practices—Lincoln and Hobart specs are close, and it meets basic ASME codes for non-critical welds. For verticals, weave a bit wider; overhead? Shorter stickout to control the puddle. Test it: Weld a T-joint, hammer it—solid? You’re golden.

How to Choose the Right Flux Core Wire for Your Project

Wire choice is where newbies trip—it’s not just diameter; it’s the flux recipe inside. For mild steel, I’m all about E71T-GS self-shielded: All-position, gasless, and tough as nails for 1/8-inch to 1/2-inch stock. Why? It flows smooth, penetrates like a champ, and handles outdoor work without fuss. I’ve run spools of Lincoln Innershield NR-211-MP on everything from farm gates to hot rod chassis—reliable, low spatter if set right.

When to grab .030″ over .035″? Thin stuff like auto body patches—less heat input, less warp. For beefier repairs, like mending a cracked loader bucket, .035″ or .045″ digs deeper. Practical know-how: Store it dry; moisture in the flux turns your bead into Swiss cheese.

Early on, I left a spool in the truck bed during a rainy week—welded a hitch, got porosity like bubble wrap. Baked it at 250°F for an hour, problem solved.

Dual-shield E71T-1? That’s gas-assisted, for when you want MIG cleanliness with flux punch—75/25 Ar/CO2 mix. Pros use it indoors for code welds; I do for shop fab where wind’s not an issue. Cost? Self-shielded’s cheaper long-term—no gas refills—but dual-shield’s bead looks prettier, less slag pecking.

Match to your machine: Hobby 140-amp units? Stick .030″. Pro 250-amp? Go .045″ for speed. Filler compatibility: ER70S-6 solid wire’s cousin, but flux adds deoxidizers for dirty steel. Tip: Buy from US makers like Hobart—consistent flux means predictable arcs.

Step-by-Step Guide to Setting Up Your MIG Welder for Flux Core

Setting up ain’t rocket science, but skip a step, and you’re chasing gremlins. I’ve flipped more polarity switches than I care to count—here’s the drill, straight from my bench.

First, safety check: Gloves on, hood down, area clear of flammables. Fire extinguisher handy—flux core sparks like fireworks.

Step 1: Swap polarity. Open the wire compartment—ground to positive, gun to negative (DCEN). Gas MIG’s reverse; forget this, and your wire stubs like a bad date.

Step 2: Load the wire. Unspool .030″ E71T-GS, cut the end square, feed through the liner—straighten that last foot or it’ll birdnest. Set drive roll tension: Pinch-test the outgoing wire; medium glove squeeze stops it. Knurled rolls only—smooth ones crush the tube.

Step 3: Prep the gun. V-groove contact tip sized to wire (.030″ tip for .030″ wire). Ditch the gas nozzle—it’s dead weight for self-shielded. Trim liner if it’s kinked; I do this every spool.

Step 4: Ground it solid. Clamp to clean metal—no paint, no rust. Loose ground? Arc wanders, settings go haywire.

Step 5: Dial the chart. For 1/4″ mild steel, 225 IPM WFS, 19V. Trigger test: Smooth hum, no stutter. Puddle forms quick? Good.

Step 6: Joint prep. Bevel thick edges 30 degrees, tack every 3 inches—prevents blow-through on fillets.

Last, test bead on scrap. Drag steady, listen for that bacon sizzle. Too ropey? Up voltage a tick. Burnback? Cut WFS. I once wired a toolbox wrong—took an hour to trace. Now? Checklist taped inside the door.

Flux Core vs Gas MIG: Which One Wins for Your Shop?

I’ve run both—gas MIG for clean indoor work, flux core when the weatherman lies. Gas MIG’s the polished pro: Solid wire, Ar/CO2 shield, silky beads with zero slag. Great for thin sheet, like HVAC ducts or bike frames—less spatter, easier cleanup. But outdoors? Wind kills the gas plume, porosity city.

Flux core flips the script: Self-shielded, wind-proof, deeper penetration for rusty beams or field repairs. Deposition’s faster—I’ve filled a 3/8″ groove in half the passes. Cons? More smoke, spatter cleanup’s a chisel workout, and beads need grinding for pretty. Gas MIG’s versatile with gas swaps; flux core’s locked to mild steel mostly.

Pros of flux: Portable (no tank), forgiving on prep, strong on thick stuff. Cons: Slag pecking, worm tracks if voltage’s high. Gas MIG pros: Clean finish, multi-metal (alum with tri-mix), low fumes. Cons: Gas costs add up, indoor-only really.

When to pick? DIY trailer hitch—flux core, quick and dirty. Custom furniture—gas MIG for that showroom shine. Me? Dual setup: Flux for rough, gas for fine. Both meet AWS codes if set right, but flux edges out for cost on big jobs.

Essential Safety Gear and Practices for Flux Core Welding

Welding’s no joke—I’ve got the scars to prove it. Flux core amps up the heat: More UV, fumes from flux burning off manganese and such. Start with the basics: Auto-darkening hood (shade 10-13), leather jacket, FR pants tucked into steel-toe boots. Gloves? MIG-style, gauntlet length—spatter bounces hot.

Ventilation’s king: Flux smoke’s thicker than gas MIG; run a shop fan or exhaust hose. Outdoors? Bonus, but watch wind direction. Eyes? Safety glasses under the hood—sparks love eyelids. And hearing? That arc crackle’s loud; plugs if you’re grinding slag all day.

Practical: Fire watch post-weld—sparks hide in cracks. Hydrate; heat builds fast. Anecdote: Buddy ignored fumes in a closed trailer—dizzy spell mid-bead. Now we crack doors every time. US OSHA says monitor air if indoors; for hobby, fresh air rules. Ground faults? GFCI your outlet. Safe? You’re welding smart.

Common Mistakes with Flux Core MIG Welding and Quick Fixes

Everyone botches a bead—me included. Top goof: Wrong polarity. DCEP for gas, DCEN for flux—mix ’em, arc’s erratic, spatter explodes. Fix: Double-check leads, test arc.

Birdnesting: Wire tangles in the drive rolls. Too-tight tension crushes the tube. Loosen till pinch-stop, use knurls. Burnback? Wire welds to tip—short stickout or low WFS. Trim to 3/4 inch, up the feed.

Worm tracks: Groovy lines from trapped gas. Voltage too high—drop 1-2V, check chart. Porosity? Dirty metal or wet wire—grind bright, bake spools.

Overtravel: Running ahead of the puddle—weak tie-in. Slow down, weave if needed. I rushed a fence post once—cracked under load. Lesson: Steady wins.

Spatter overload: High voltage or push technique. Drag it, fine-tune. Fix: Anti-spatter spray on tips, peck slag quick. Spot these early, and your welds stack up.

Step-by-Step Guide to Running Your First Flux Core Weld

Ready to strike? Let’s weld a lap joint on 1/4-inch mild steel—simple, useful for brackets.

Step 1: Setup per guide—DCEN, .030″ wire, 225 IPM/19V.

Step 2: Clamp pieces overlapping 1 inch, tack ends. Grind edges clean.

Step 3: Ground clamp nearby. Stance: Feet shoulder-width, gun in right hand (lefties flip).

Step 4: Trigger on, arc starts—listen for steady sizzle. Drag gun 15 degrees back, 3/4-inch stickout. Travel slow, like 1/2 inch per second—puddle tails your gun.

Step 5: Weave slight side-to-side on fillets for coverage. End with a quick whip to fill the crater.

Step 6: Cool, peck slag with chipping hammer, wire-brush. Inspect: Flat bead, no cracks? Hammer test it.

My first? Ugly, but it held a shelf. Practice 10 feet daily—soon it’s muscle memory. For verticals, uphill drag, shorter stickout.

Real-World Applications: From Garage Builds to Job Site Repairs

Flux core shines in the trenches. Garage? Patch a rusted truck bed—deep penetration eats scale, quick tacks hold panels. I’ve fabbed a workbench from scrap angle; .035″ wire at 200 IPM, done in an afternoon.

Hobbyists: Custom motorcycle swingarm—light prep, all-position wire for overhead tubes. Pros: Bridge girders or pipeline skids—E71T-1 dual-shield meets D1.1 codes, fast fill on multi-pass.

Students: Practice fillets on pipe for certs—forgiving arc teaches control. Industry: Heavy equip repair, like boom cracks—portable, no gas hassle in the field.

US twist: Follow API 1104 for pipes, AWS for structures. Example: Farm gate repair—1/4″ chain link frame, flux core zipped it wind-proof. Cost? Spool’s $20, job’s done.

Advanced Tips for Dialing In Perfect Beads Every Time

Once basics click, level up. Travel speed: Too fast, convex bead—slow for flat. Angle: 10-15 degrees drag for penetration; 0 for butt joints.

Puddle watch: Shiny? Good flow. Dull? Add heat. For overhead, flick upward to control drip.

Machine tweaks: Synergic? Override for flux—it’s touchy. Clean liner monthly; kinks kill feed.

Anecdote: Job site vertical up on column—wove too wide, undercut. Fixed with tighter weave, 18V. Pro: Preheat thick steel 100°F—less cracking.

Joint prep: V-groove 60 degrees for butts, 45 for fillets. Filler: Match tensile, overfill 1/16 inch.

Conclusion: Nail Your Welds and Weld with Confidence

We’ve covered the flux core MIG welding settings chart, wire picks, setups, mistakes, and more. Start with the chart, test on scrap, drag that gun like you mean it. Polarity and prep are your foundations; ignore ’em, and nothing else saves you. Now you’re geared to pick the right process—flux for rugged, gas for finesse—and tweak for integrity that lasts.

You’re more prepared because you know why it matters: Safety from stable arcs, strength from deep ties, efficiency from fast beads. Go build that trailer or repair that loader—confident action beats hesitation every time. Keep a log of your settings per job; it’ll shave hours off future tweaks. Now, fire up that machine—you got this.

FQAs

What Is the Ideal Stickout Length for Flux Core MIG Welding?

Aim for 1/2 to 3/4 inch on most setups—keeps the arc tight without burnback. For thicker stock, stretch to 1 inch, but test it; too long, and the puddle wanders.

Can Beginners Use Flux Core MIG Welding on Thin Metal?

Absolutely, but dial low: .030″ wire at 150 IPM/16V for 1/8-inch sheet. Drag slow to avoid warping—practice on scrap first, or you’ll punch holes like Swiss cheese.

Why Do My Flux Core Welds Have Worm Tracks?

That’s trapped gas from high voltage—drop 1-2V per the chart. Check stickout too; over 1 inch lets flux gases bubble weird. Clean your bead, and it’ll smooth out.

Is Flux Core Welding Stronger Than Gas MIG for Structural Work?

It can be, thanks to deeper penetration on dirty steel—E71T-GS hits 70ksi tensile easy. But gas MIG’s cleaner for code aesthetics. Match to your AWS spec, and both hold.

How Often Should I Clean My MIG Gun for Flux Core?

After every spool, or when spatter builds—chip slag daily. Lint-free rag with solvent on the nozzle; neglect it, and birdnesting turns your afternoon into frustration.